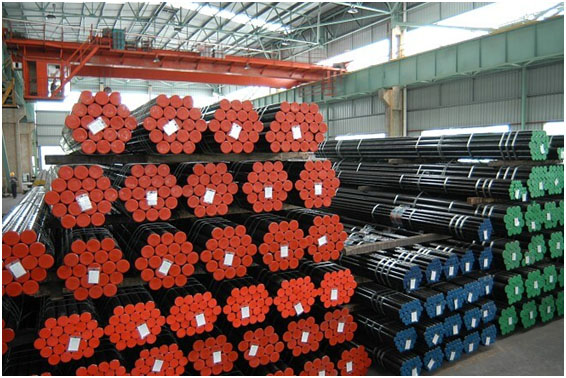

China, 10th Nov 2023- In an era marked by rapid technological evolution, the industrial realm witnesses yet another groundbreaking stride with the advancements in pipe technologies. These aren’t just tubes of metal anymore; they are emblematic of engineering finesse, reflecting innovation at its peak. Serving as the lifeblood in a multitude of industries, from energy to infrastructure, these modern pipes are not only enhancing operational efficiency but are also setting new benchmarks in safety and durability.

Powder-Coated Pipe Spotlight

In the realm of advanced industrial solutions, powder-coating technology emerges as a game-changer for pipe protection. Through a meticulous process where powdered paint is electrostatically applied and then cured under heat, it forms a skin-like protective layer on the pipe’s surface.

The industry, always in pursuit of robust and lasting materials, has warmly embraced the powder-coated pipe. Their unparalleled corrosion resistance ensures that structures remain uncompromised even in the harshest environments.

The Evolution of Coating Steel Pipe

Coating Steel Pipe, long celebrated for their strength and versatility, have always grappled with one primary nemesis: the external environment. Whether it’s the relentless onslaught of moisture, corrosive chemicals, or even sheer physical abrasion, unprotected steel, despite its robustness, often finds itself at odds with these elements. This very challenge birthed the drive for advanced coatings, a relentless pursuit to armor steel pipes against the vagaries of their surroundings.

The Seamless Transition: CS Seamless Pipe

Traditionally, CS Seamless Pipe and carbon steel pipe manufacturers is made by bending sheets of metal and then welding them, resulting in a seam. However, seamless pipes, as the name suggests, are devoid of this welded seam. They are produced by piercing a solid billet of steel and then elongating it, ensuring no seams are present. This intricate manufacturing process not only requires precision but also a thorough understanding of metallurgy.

Welding Reimagined: ERW Carbon Steel Pipe

Electric Resistance Welding (ERW) carbon steel welded pipe, at its core, employs electrical currents to generate heat at the weld interface, fusing the edges of the steel strip to form a pipe. The world of welding, long rooted in traditional techniques, has witnessed transformative shifts. Among the front-runners of this change is the Electric Resistance Welding (ERW) method, specifically tailored for carbon steel pipes. ERW is more than just a technique—it’s a reimagining of how welding can be optimized for specific applications.

Standardizing Excellence with API Seamless Pipe

In the intricate world of the oil and gas sector, the need for standardized, reliable, and high-performing materials cannot be overstated. Leading this charge is the American Petroleum Institute (API), whose guidelines and standards have transformed the industry’s landscape, with the API Seamless Pipe being a prime testament to this excellence.

The API, since its inception, has been the vanguard of setting standards that ensure safety, sustainability, and efficiency in the oil and gas industry. By stipulating rigorous specifications and quality benchmarks, API ensures that equipment and materials, including pipes, align with the sector’s demanding and ever-evolving needs.

Wrap-Up: The Dawn of a New Piping Era

As we navigate the corridors of industrial evolution, it becomes unmistakably clear that the modern advancements in piping are not mere upgrades, but transformative shifts. These innovations, from powder coatings to ERW techniques and API standards, symbolize the fusion of science, technology, and foresight.

With so much potential on the horizon, it’s imperative for industries to not just acknowledge but actively embrace these pioneering solutions. The future beckons, not just with promise but with a challenge – a challenge to adapt, innovate, and lead.

Media Contact

Organization: slpipeline

Contact Person: slpipeline

Website: https://www.slpipeline.com/

Email: [email protected]

Contact Number: +86-21-68415587

Address:10A6, No 526, Laoshan Road, Pudong New District, Shanghai, China

Country:China

Release id:7651

View source version on King Newswire:

Revolutionizing Industries: A Closer Look at Emerging Pipe Technologies and Coatings

Information contained on this page is provided by an independent third-party content provider. Binary News Network and this Site make no warranties or representations in connection therewith. If you are affiliated with this page and would like it removed please contact [email protected]

Comments